Have you ever wondered about how to locate good water - or a variety of other things? If you are going to drill a bore or well, you don't want to spend all that money drilling in just any old place and possibly end up with a dry hole. You want the best chance of yielding water the first time,

There are couple of methods to determine where to drill and maximise your chance of finding good water. There are scientific methods such as using geology, satellite photos or proton magnetic resonance (PMR) investigations, and there is dowsing.

Depending on your established belief systems, you will relate to the following or not. If you do, you will find it fascinating. Personally and from diverse first hand experiences over the years I will say that I believe it has a lot of credence.

Dowsing has been used for thousands of years. As with any other method of doing anything, there are exceptional dowsers and not so effective ones. Personally I rely on word of mouth and evidence of success when choosing any service or provider. Steven G. Herbert from The American Society of Dowsers has graciously supplied us with a fascinating article and explanation on the history of dowsing, what it can do and how it works.

‘Indago Felix’ – Latin for “The Fruitful Search”. This is the motto of The American Society of Dowsers, emphasizing the immense practicality of this ancient art. And what could be more practical than the location of underground water, the lifeblood of the earth? Indeed, the word “dowsing” likely evokes a stereotypic image of an old farmer in coveralls trudging across his fields with a forked stick. Beyond the stereotypes, however, in reality, people of all professions and all walks of life practice dowsing in an infinite number of applications.

Dowsing can be defined as “The search for information by means of a hand-held instrument and faculties beyond the five physical senses”. There are two basic types of dowsing; tangible target and informational. However, whether one is searching for a physical object or substance, or for pure information, ultimately all dowsing is a search for information. It is accomplished by tapping into a higher level of mind and spirit. The search is facilitated by four main types of dowsing instruments employed by modern dowsers; the Y-rod, L-rods, pendulum and bobber. By itself, the tool detects nothing, but merely functions as a “read-out device”. It is the body and the auric field which is the detector and receptor. Ultimately, it is the goal of all dowsers to someday be able to dispense with the tools all together and receive information directly to consciousness.

The ability to find water beneath the ground by dowsing is innate, if often latent, in all humans. It is an inheritance from our animal ancestry, a sense that evolved from obvious survival value. Animals are natural “deviceless” dowsers, their ability also being closely related to the capacity to sense the electromagnetic fields of the earth, which they use for orientation or migration. Anyone can dowse, though for some it is a skill which will come quickly and naturally, while for others it must be developed slowly. Oddly, whether it comes immediately or with time does not seem to depend on whether you are a believer or a skeptic. It matters more what you believe subconsciously.

The ability to find water beneath the ground by dowsing is innate, if often latent, in all humans. It is an inheritance from our animal ancestry, a sense that evolved from obvious survival value. Animals are natural “deviceless” dowsers, their ability also being closely related to the capacity to sense the electromagnetic fields of the earth, which they use for orientation or migration. Anyone can dowse, though for some it is a skill which will come quickly and naturally, while for others it must be developed slowly. Oddly, whether it comes immediately or with time does not seem to depend on whether you are a believer or a skeptic. It matters more what you believe subconsciously.

Humans have dowsed all through the ages. Paintings on cave walls in the north of Africa dating back 8,000 years can be interpreted as a dowser holding a forked stick. Depictions on pottery and tomb walls show dowsing instruments such as staffs being used by ancient Egyptians and Etruscans. Coins, figurines, and other artifacts depict dowsing in use throughout the Mediterranean and Mesopotamian worlds. A 4,000 year old bas relief with inscription at the dawn of historical times speaks of dowsing by the Emperor of China. Many passages in the Bible elude to dowsing. This art was brought to America by Europeans, who used it extensively for the location of both water and minerals.Having been well established in the collective unconscious for many millenniums before, one may likely experience today an immediate response from the dowsing instrument. However, it is important to emphasize that dowsing is ten percent getting a reaction and ninety percent developing accuracy. The three keys to accuracy are; attunement to the Source, resonance with a clearly defined target, and concentration on the right question. With practice, patience and experience, one can expect over time to move through seven levels of dowsing proficiency; 1) location of physical objects on site, 2) detection of tangible targets at a distance and up to the horizon, 3) remote location of physical targets, 4) informational dowsing, 5) cooperation with nature, 6) co-creation with nature, and 7) conscious union with creative forces.Accuracy in dowsing also depends on following correct procedure, observing proper ethics, and avoiding interference factors. Correct procedure begins with clearly establishing codes, so that the movements of the instrument can be correctly interpreted. It is of utmost importance to start any dowsing session by first identifying the source of your information, and insuring that it is from only the Highest and Purest level. Otherwise, your dowsing will be no better – or no safer – than using a Ouija board. One must establish that he or she has the permission to dowse a particular subject or object of search, that one has the ability to do so with accuracy, and that all is in proper timing. It is crucial to proceed with the proper attitude of faith, trust, respect, sincere motivation, and true need. Ethics should be maintained so that dowsing is not abused for greed or selfishness, the compulsion for ego control and manipulation, or to intrude on another’s privacy or free will. Interference factors to avoid can range from the purely physical, such as drinking too much coffee, to serious spiritual blockages, such as psychic invasion. Both strong mental bias or emotional attachment can also distort the answer.

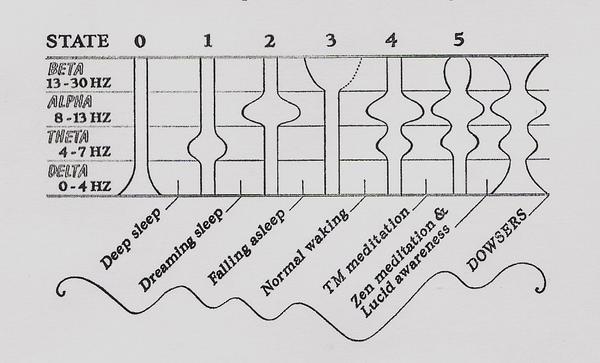

How does dowsing work? There are as many theories as there are dowsers, but that which carries the most consensus is one which involves several levels of mind. A question is posed to the subconscious mind, which relays the question to the superconscious mind. The subconscious then conveys the answer to the conscious mind by means of the movements of the dowsing instrument. Studies of the brain wave frequencies of dowsers* seem to support this hypothesis, in showing that dowsers are able to function on several frequencies at once (beta, alpha, theta and delta, corresponding to the waking state, reverie, dream sleep and deep sleep, respectively). Not even transcendental meditation could match this. Because of the nature of the subconscious, one must phrase questions in precisely literal and specific terms. This is the real art of dowsing, to ask the right question. However, correct interpretation of the dowsing response is also very important.

The search for underground water is the best example of the great practicality of the dowsing art. Typically, dowsers search for “living water”, that is, water which comes from the depths of the earth, rising to form domes, and extending out laterally in pressure-flowing veins. Such water is much purer, a more steady and reliable supply, and sometimes is found at shallower depths than the static groundwater found in aquifers. A dowser may also find below the surface, oil, gas, minerals, archaeological sites, buried treasure, or underground utilities.

One may more often use dowsing in daily life to locate objects on the surface of the ground. You may want to find your car in the parking lot, for example, or locate your lost car keys, a missing checkbook, or a misplaced remote. Dowsers are often asked to find missing persons or pets, or help the police solve crimes. One can also dowse less tangible targets, such as in determining the health of a place by dowsing the geopathic or geovitalizing energies. Informational dowsing can be employed in making dietary decisions, such as choosing vitamins and supplements, for example. You may use it to determine the best course of action or the solution to a problem, whether it be in job hunting, looking for a house or apartment, or seeking a healthy relationship. Another practical application is in gardening; dowsing soil conditions, amendment needs, time to plant, expected weather conditions, etc. The potential uses are limitless.

All dowsers vary as to what application they specialize in and excel at. They also differ in which of a great variety of dowsing instruments work best for them. What they all have in common, however, is the empowerment dowsing gives them. Its practice facilitates the connection to Higher levels of Mind and Spirit, with simple, inexpensive and readily available tools. Trust in the direction and guidance of the Source of All leads to a life lived more in alignment with one’s own soul purpose, as well as with the Universal Plan. In other words, dowsing opens one to a Greater Reality and the joy of feeling a valued part of the Whole, as well as the sense of fulfillment that comes with fruitful service.

* “Brain Characteristics of Dowsers” by Edith M. Jurka, M.D. in The American Dowser February 1983 23(1):5-11

Steven Herbert is a geologist, anthropologist, development worker, writer and international dowser.

For more information on The American Society of Dowsers and the location of a local chapter near you, visit the website at www.dowsers.org.

I trust that you found this information interesting and hopefully valuable and of course once you have found water, consider a Brumby Pump to bring it to the surface, while treating it at the same time www.brumbypumps.com